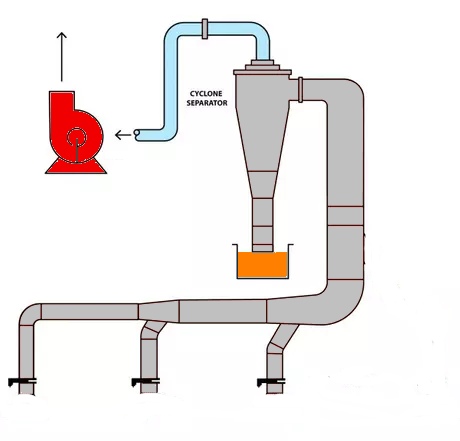

Sawdust from woodworking builds up and floats in the atmosphere - as part of the workshop design I created a "dust extraction" system that collects dust and other debris and deposits it in a bin for disposal.

Sawdust from woodworking builds up and floats in the atmosphere - as part of the workshop design I created a "dust extraction" system that collects dust and other debris and deposits it in a bin for disposal.

![]() The text (with more photographs) is also published as a .pdf document

The text (with more photographs) is also published as a .pdf document

- click the icon to open the file and download

Small workshop dust extraction

My workshop is a single garage that also houses the CH boiler and HW tank as well as a cycle maintenance bench/tool-board and storage of 3 bicycles.

The simple and effective system was created from 40mm waste pipe and push fittings connected to a Henry vacuum cleaner, with home-made blast gates and 38mm flexible pond hose - with various connectors.

The simple and effective system was created from 40mm waste pipe and push fittings connected to a Henry vacuum cleaner, with home-made blast gates and 38mm flexible pond hose - with various connectors.

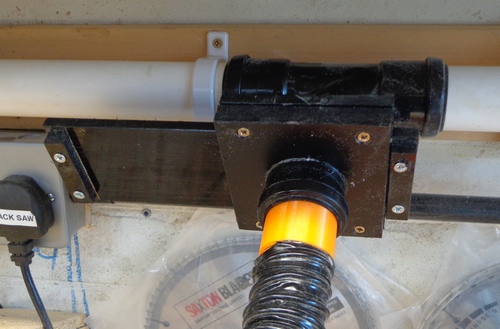

The waste pipe run is attached to the wall with plastic pipe clips about 40cm above the bench-top level, parallel to the electrical conduit run and power sockets. Waste pipe T-connectors are positioned at appropriate points on the pipe run with blast-gates - made from polycarbonate sheet and glued to the T connectors. For stability the T-connectors are fixed to the waste pipe with a small self-tapping screw.

The duct pipe connects with a flexible pond hose to a cyclone fixed to an approx 40 cm cube bin made from OSB, with all the joints on the inside caulked and a cased lid, with an all-round seal of draught excluder rubber, held closed with over-centre clamps. (I did experiment with a plastic drum but the suction caused it to collapse)

Each of my machines has a hose connected to it (the ports all vary in size!) and either remain connected to the extraction system semi-permanently or are connected when the machine is in use - e.g. the mitre, track and band saws are connected all the time - the table saw is on wheels, stored under the bench with the router table and they are only connected when in use. A few hand machines (router, jigsaw, circular saw, sander) have dust-ports that can be connected to the system with a hose when in use.

I also have a separate hose with the Henry’s furniture crevice tool attached to it for cleaning up benches, machines etc. - it plugs into one of the blast gates (Easier and quicker than disconnecting the Henry’s hose from the system)

The dust separation is excellent with very little getting past the cyclone to the Henry’s bag - using the planer/thicknesser machine isn’t so successful as the waste is significantly larger. The only issue is remembering to open the appropriate blast gate and switch on the suction before using each tool!

There is also have a Record AC400 air-cleaner/filter attached to the ceiling that significantly reduces the dust in the atmosphere not captured by the extraction system.

The diagram illustrates the principles of the dust extraction system - the inlets/blast gates at the bottom and the fan (vacuum cleaner) pulling the air through the ducting into the cyclone which rotates the sawdust particles to drop into the collecting bin below.